Anping County Wennian Wire Mesh Products Co., Ltd. offers a wide range of plastic netting and solutions across multiple industries and detailed applications.

Global desertification is becoming more and more serious, the austere reality of the relative shortage of raw materials used in the fight against desertification force the researchers of wind-blown sand theory to develop new materials with sand protection function and gradually replace the previous sand prevention materials (crop straw and so on). From the application scope of sand control materials, it is mainly used for sand fixing (lattice sand barrier) and sand blocking measures (sand barrier). Sand barrier, also known as high vertical sand barrier, is one of the most important measures to prevent and control desertification at present. It has been widely used in the vast sandy areas in China as an early measure for sand fixing afforestation or an independent sand prevention measure for heavy sand disaster areas. Especially in recent decades, a great deal of research has been carried out on the role of barriers in the control of wind blown sand disasters, and some substantial progress has been made. Nylon and plastic net as a new type of sand control material, although the cost is relatively high, but can continuously improve its anti-aging properties and sand resistance. It also has the advantages of industrialized production and easy construction, etc. Especially in some areas with serious wind and sand disaster, such as industrial and mining, transportation and national defense, nylon and plastic nets are used as sand prevention materials. The protective effect is very obvious and has broad application prospects. In addition, nylon and plastic nets have longer service life than crop straw and are non perishable. Although its disposable investment cost is higher, but the total economic benefits is reasonable and effective. at the same time, it is conducive to the improvement of the ecological environment, and is much better than the general ones in the process of sand barrier. In this paper, the wind tunnel simulation of different structures of nylon and plastic net is carried out to provide the theoretical basis for the optimization design and application of field sand control project.

Influence of porosity on sand control effect

Because of the different material and weave structure of the new sand protection material, the effect of porosity on the sand flow is difficult to reformed into a unified system to be compared. According to the observation and research to the role of barriers with different porosities and heights in preventing the accumulation of sand in front of the fence, it is found that the fence porosity is the most important factor affecting the protection efficiency. One is due to the effect of obstructing fence itself outside the quicksand; the other one is the effective protection of the fence porosity range or sediment accumulation range. As shown in Table 1, the maximum value in the unit time of barrier sediment (q1 + q2) occurs when the porosity is about 40%. Laboratory experiments and field observations have proved that when the porosity reaches about 40%, the effect of barrier sand is best.

| Observation content | Standard porosity β (%) batten test fence | |||||

|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | |

| q 1 / (g · cm-1 · min-1) | 0.823 | 0.310 | 0.582 | 2.459 | 1.528 | 1.224 |

| q 1 / (q 1 + q 2) / % | 95.5 | 92.8 | 91.5 | 90.6 | 81.9 | 78.7 |

| V 1 / (m · s-1) | 8.1 | 5.8 | 5.5 | 7.3 | 8.2 | 7.6 |

| q 2 / (g · cm-1 · min-1) | 0.039 | 0.024 | 0.054 | 0.254 | 0.337 | 0.332 |

| q 2 / (q 1 + q 2) / % | 4.5 | 7.2 | 8.5 | 9.4 | 18.1 | 21.3 |

| V 1 / (m · s-1) | 8.7 | 7.4 | 6.5 | 8.3 | 8.3 | 8.1 |

| q 1 + q 2 | 0.862 | 0.334 | 0.636 | 2.713 | 1.865 | 1.556 |

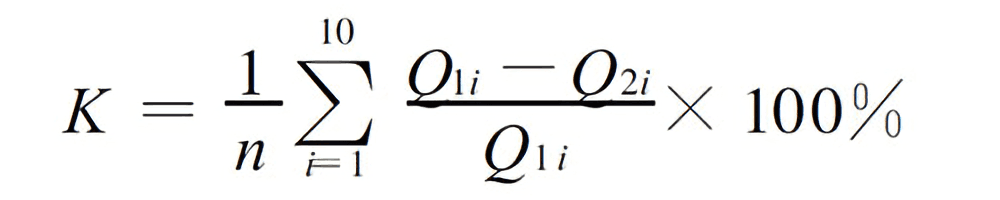

The results show that the resistance of the barrier is mainly affected by the porosity and height, moreover, the saltation lift force of sand grains is also related to the size of incoming air flow and the friction velocity of sand bed. Through researching the effect of the fence porosity, hole shape to the wind weakened, the re-circulation zone length and Reynolds shear stress, it is found that when the porosity is more than 30%, the vortex formed by the fence will disappear. In the absence of fences, the airflow accelerated along the windward slope of the dunes and separated at the top of the dunes. When a barrier with different porosities is installed, the airflow is separated at the top of the fence. Shear flow which has lower separation acts directly on the top of the dunes and forms a vortex along the windward slope of the dune behind the fence. The flow over the fence forms a more complex turbulent flow with the interaction of the laminar flow through the fence. An irregular quadrilateral turbulent flow zone with barriers, sand bed surfaces, dune windward slopes and upper separate shear layers is formed behind the barrier. It can be seen that the barrier porosity not only influences the cross flow ability of sand particles directly, but also changes the turbulence characteristics of the airflow around the fence. Finally, it has a crucial impact on its protection effectiveness. The study shows that an airtight baffle with zero porosity can also resist sand. However, the quicksand can only be blocked within twice the height of the barrier. This effect decreases with the increase of the plate height, and with the increase of porosity. At the same time, the sand blocking capacity and protection range also increase correspondingly. The inlet indicating wind speed is set at 10 m · S-1 and the net height is 10 cm to carried out he wind tunnel simulation experiments of sand barrier with different porosities. In addition, the average net sand retention rate of nylon net fence under various wind speeds is calculated. The formula is as follows:

| Porosity β (%) | Sediment transport rate q / (g · cm-2 · min-1) | Net sand resistivity K (%) | Sand control effect | Sand content and percentage of weight at different heights (cm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| In front of the net | Behind the net | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |||

| 35 | 1.84 | 0.24 | 52.81 | Q1i / g | 97.23 | 47.83 | 29.619 | 20.15 | 9.922 | 7.548 | 3.883 | 2.379 | 1.638 | 0.907 |

| Q1i / % | 43.97 | 21.63 | 13.40 | 9.11 | 4.49 | 3.41 | 1.76 | 1.08 | 0.74 | 0.41 | ||||

| Q2i / g | 0.401 | 0.934 | 1.452 | 2.059 | 2.853 | 3.186 | 3.839 | 4.479 | 4.75 | 5.23 | ||||

| Q2i / % | 1.37 | 3.20 | 4.98 | 7.06 | 9.78 | 10.92 | 13.16 | 15.35 | 16.28 | 17.92 | ||||

| Q1i / Q2i | 242.5 | 51.21 | 20.40 | 9.79 | 3.48 | 2.37 | 1.01 | 0.53 | 0.34 | 0.17 | ||||

| 40 | 1.47 | 0.15 | 55.42 | Q1i / g | 90.64 | 31.12 | 17.42 | 11.89 | 6.02 | 5.58 | 3.21 | 2.59 | 2.40 | 1.9 |

| Q1i / % | 52.46 | 18.01 | 10.08 | 6.88 | 3.48 | 3.23 | 1.86 | 1.50 | 1.39 | 1.10 | ||||

| Q2i / g | 2.86 | 4.35 | 5.65 | 6.86 | 8.82 | 9.58 | 11.92 | 14.13 | 15.65 | 16.88 | ||||

| Q2i / % | 2.96 | 4.50 | 5.84 | 7.09 | 9.12 | 9.91 | 12.33 | 14.61 | 16.18 | 17.46 | ||||

| Q1i / Q2i | 31.71 | 7.15 | 3.08 | 1.73 | 0.68 | 0.58 | 0.27 | 0.18 | 0.15 | 0.11 | ||||

| 55 | 0.86 | 0.48 | 57.40 | Q1i / g | 89.71 | 33.49 | 19.79 | 13.30 | 6.58 | 5.33 | 2.96 | 2.12 | 1.68 | 1.20 |

| Q1i / % | 50.92 | 19.01 | 11.23 | 7.55 | 3.74 | 3.03 | 1.68 | 1.21 | 0.95 | 0.68 | ||||

| Q2i / g | 2.25 | 2.52 | 2.18 | 1.83 | 1.72 | 1.47 | 1.54 | 1.62 | 1.66 | 1.74 | ||||

| Q2i / % | 12.17 | 13.59 | 11.79 | 9.85 | 9.28 | 7.91 | 8.33 | 8.74 | 8.95 | 9.41 | ||||

| Q1i / Q2i | 39.80 | 13.31 | 9.06 | 7.29 | 3.83 | 3.64 | 1.92 | 1.31 | 1.01 | 0.69 | ||||

| 60 | 1.20 | 0.46 | 47.64 | Q1i / g | 64.38 | 32.12 | 19.24 | 12.46 | 5.76 | 4.37 | 2.21 | 1.41 | 1.06 | 0.68 |

| Q1i / % | 44.81 | 22.35 | 13.39 | 80.67 | 4.01 | 3.04 | 1.53 | 0.98 | 0.74 | 0.47 | ||||

| Q2i / g | 9.56 | 8.32 | 7.02 | 5.88 | 5.24 | 4.22 | 4.14 | 3.90 | 3.67 | 3.52 | ||||

| Q2i / % | 17.23 | 15.01 | 12.66 | 10.60 | 9.44 | 7.61 | 7.47 | 7.03 | 6.61 | 6.34 | ||||

| Q1i / Q2i | 6.74 | 3.86 | 2.74 | 2.12 | 1.10 | 1.03 | 0.53 | 0.36 | 0.29 | 0.19 | ||||

| Wind speed (m·s-1) | Sediment transport rate (g · min-1 ·cm-2) | Sand control effect | Sand content and percentage of weight at different heights (cm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | Average | |||

| 8 | 0.16 | Q1i / g | 43.27 | 10.65 | 5.08 | 2.73 | 0.98 | 0.79 | 0.41 | 0.32 | 0.49 | 0.24 | |

| Q1i / % | 66.58 | 16.38 | 7.81 | 4.20 | 1.51 | 1.18 | 0.63 | 0.60 | 0.75 | 0.36 | |||

| Q2i / g | 0.75 | 0.91 | 1.22 | 1.43 | 2.00 | 2.23 | 2.74 | 3.22 | 3.41 | 3.36 | |||

| Q2i / % | 3.51 | 4.30 | 5.73 | 6.71 | 9.42 | 10.49 | 12.85 | 15.15 | 16.02 | 15.82 | |||

| Q1i / Q2i | 57.93 | 11.65 | 4.16 | 1.91 | 0.49 | 0.34 | 0.15 | 0.12 | 0.14 | 0.07 | 7.70 | ||

| 10 | 0.86 | Q1i / g | 90.64 | 31.12 | 17.42 | 11.89 | 6.02 | 5.58 | 3.21 | 2.59 | 2.40 | 1.90 | |

| Q1i / % | 52.46 | 18.01 | 10.08 | 6.88 | 3.48 | 3.32 | 1.86 | 1.49 | 1.39 | 1.10 | |||

| Q2i / g | 2.86 | 4.35 | 5.65 | 6.86 | 8.82 | 9.58 | 11.92 | 14.13 | 15.65 | 16.88 | |||

| Q2i / % | 2.96 | 4.50 | 5.84 | 7.09 | 9.12 | 9.91 | 12.33 | 14.61 | 16.18 | 17.46 | |||

| Q1i / Q2i | 31.71 | 7.15 | 3.08 | 1.73 | 0.68 | 0.58 | 0.27 | 0.18 | 0.15 | 0.11 | 4.57 | ||

| 12 | 5.79 | Q1i / g | 100.3 | 44.41 | 28.43 | 19.55 | 11.9 | 9.81 | 5.85 | 4.51 | 3.91 | 2.95 | |

| Q1i / % | 43.29 | 19.16 | 12.17 | 8.44 | 5.18 | 4.23 | 2.53 | 1.95 | 1.69 | 1.26 | |||

| Q2i / g | 5.10 | 7.01 | 8.09 | 8.61 | 9.72 | 10.49 | 12.28 | 13.94 | 14.19 | 14.81 | |||

| Q2i / % | 4.89 | 6.72 | 7.76 | 8.26 | 9.33 | 10.06 | 11.78 | 13.37 | 13.61 | 14.22 | |||

| Q1i / Q2i | 19.69 | 6.34 | 3.51 | 2.27 | 1.23 | 0.94 | 0.48 | 0.32 | 0.28 | 0.20 | 3.53 | ||

| 14 | 13.86 | Q1i / g | 111.42 | 50.91 2.623 |

34.59 | 24.27 | 16.2 | 13.48 | 8.75 | 7.12 | 5.83 | 4.54 | |

| Q1i / % | 40.21 | 18.38 | 12.48 | 8.76 | 5.85 | 4.86 | 3.16 | 2.57 | 2.10 | 1.63 | |||

| Q2i / g | 5.38 | 6.06 | 8.10 | 8.68 | 9.67 | 9.72 | 10.99 | 12.40 | 13.21 | 14.05 | |||

| Q2i / % | 5.48 | 6.17 | 8.24 | 8.83 | 9.84 | 9.89 | 11.18 | 12.62 | 13.44 | 14.31 | |||

| Q1i / Q2i | 20.71 | 8.40 | 4.27 | 2.80 | 1.68 | 1.39 | 0.80 | 0.57 | 0.44 | 0.32 | 4.14 | ||

Give us a call or write us a message.

We are happy to advise!